Decision intelligence that drives optimized mining operations.

- 402-15400 Croydon Drive Surrey, BC, V3Z 1K1, Canada

Decision intelligence that drives optimized mining operations.

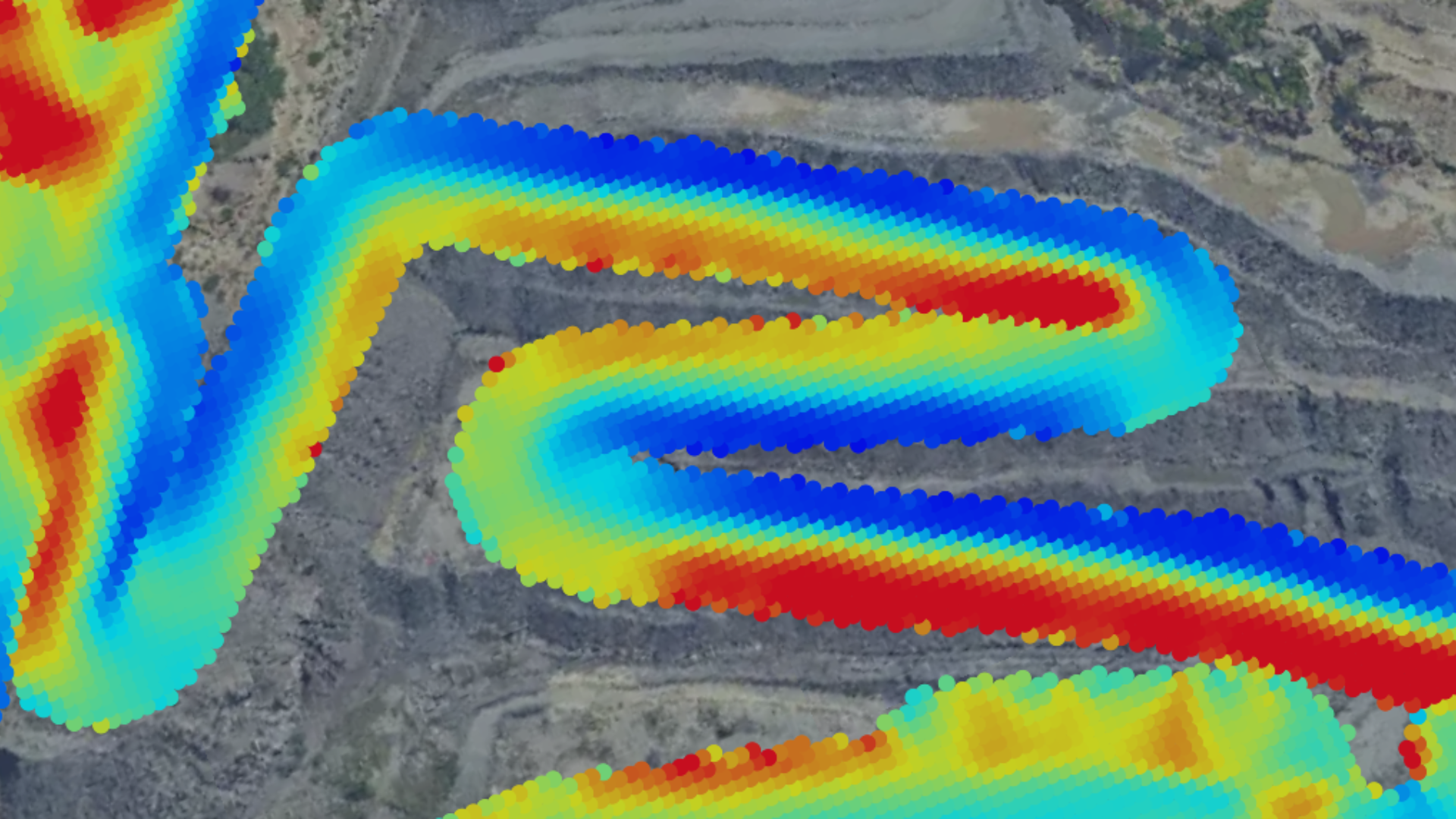

In response to rising fuel costs, operational inefficiencies, and growing sustainability pressure, one of South America’s largest open-pit coal mines partnered with Cascadia Scientific to deploy AI-driven fleet optimization tools across its operations.

Through machine learning, real-time coaching, and predictive analytics, the operation:

This operation faced mounting challenges: high diesel consumption, inconsistent operator behavior, reactive maintenance practices, and rising demands for carbon transparency and performance improvement.

Cascadia Scientific deployed its SmartRView platform and Machine Learning Coach tools across a multi-OEM fleet that included over 250 assets. The solution delivered:

Since 2023, this partnership has delivered more than 10.1 million liters of fuel savings and over 27,500 tonnes of CO₂ reductions, driven not by any one solution, but through a holistic strategy combining truck-level analytics, operator coaching, and road condition optimization.

Cascadia Scientific turned fleet-wide fuel efficiency and emissions reduction into a repeatable, scalable strategy that drives both financial and environmental results.

|

Metric

|

Before

|

After

|

Change

|

|

|---|---|---|---|---|

|

Fuel per Pass |

2.52gal |

1.00gal |

-1.52 gal |

|

|

Vibration |

High |

Reduced |

Reduced Vibration |

|

|

Braking Behaviour |

Excessive |

Normal |

Improved Operator Performance |

|

This project’s success is a direct result of strong collaboration, dedicated effort, and hands-on action from the local team. Like any data-driven solution, achieving full value depends on active involvement and follow-through at the site level. We’re proud of what’s been accomplished together and excited to see what more we can achieve as this partnership grows

If you’re looking for:

Then it’s time to move beyond dashboards—and into action.

Let’s explore how Cascadia can help your mine realize measurable, lasting impact.

Our Headquarters

402-15400 Croydon Drive

Surrey, BC, V3Z 1K1, Canada

Cascadia Scientific © 2025 All right reserved | Vancouver Web Design By BragDeal, Inc.