- 402-15400 Croydon Drive Surrey, BC, V3Z 1K1, Canada

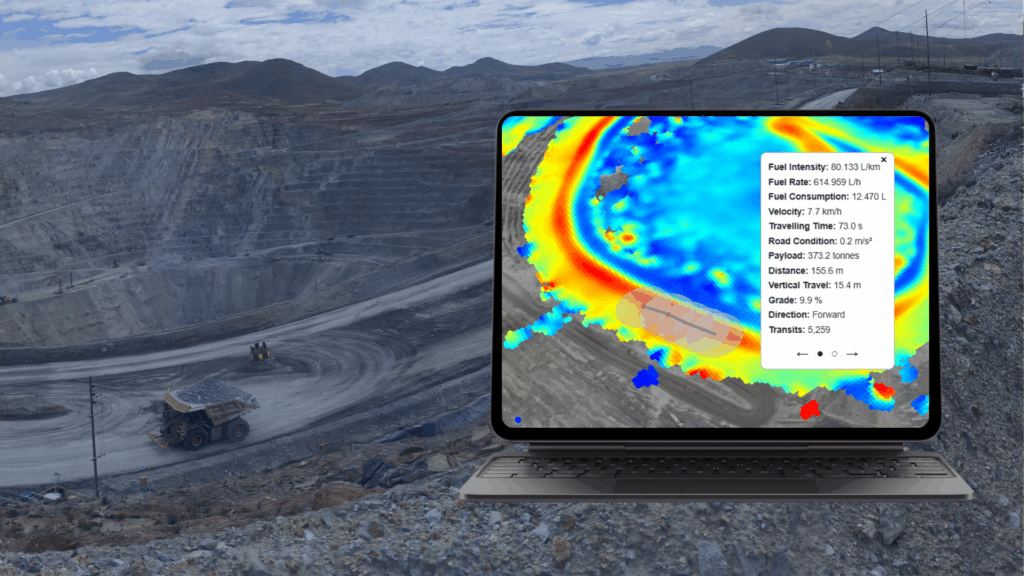

Burning fuel is necessary to get the job done. At Cascadia, we don’t just track fuel use — we help you understand when fuel consumption isn’t aligned with your productivity targets. Whether it’s on the road, in the truck, or with the operator, we identify opportunities to boost efficiency and reduce waste.

The Science of Fuel Efficiency, at Your Fingertips

Fuel Efficiency You Can Measure, Validate, and Act On

Turn Every Haul Cycle Into a Cost-Saving Opportunity

1.9M Gallons Saved | 19,400+ Tonnes CO₂ Reduced | 250+ Assets Optimized

Confirm claims from OEMs and fuel suppliers

Measure the ROI of roadwork and design changes

Surface performance gaps between drivers

Detect early signs of mechanical inefficiency

Cascadia Scientific’s Engagement Model is a closed-loop process designed to ensure measurable impact from operational interventions. It begins with identifying opportunities through data analysis, such as road upgrades, equipment maintenance, or operator performance improvement, and proceeds to scope the size and potential value of those opportunities. Once the customer takes action based on these insights, they notify Cascadia of the changes. From there, Cascadia calculates fuel savings, assesses the durability of the intervention, and conducts statistical analysis to validate the results. This cyclical model ensures all insights are grounded in measurable outcomes.

Cascadia analyzes mine site data to identify performance improvement opportunities.

Potential improvements are scoped for size, impact, and feasibility.

The customer implements recommended interventions (e.g., roadwork, maintenance, operator training).

Cascadia compares performance before and after the intervention to validate impact.

The customer provides input on how long the intervention’s benefits are expected to last.

Fuel and productivity gains based on measured performance improvements

Cascadia and the customer review results together to identify further opportunities.

Our Headquarters

402-15400 Croydon Drive

Surrey, BC, V3Z 1K1, Canada

Cascadia Scientific © 2025 All right reserved | Vancouver Web Design By BragDeal, Inc.